Glass Blog

Cladding systems are external wall systems that can be applied to the outside of buildings. They are used on both residential and commercial buildings, and offer numerous benefits including additional structural protection, noise and heat insulation, and improved aesthetics.

There are several different types of cladding, all of which have various pros and cons. Read on to find out about 6 of the most common types of cladding.

Vinyl Cladding

Due to its high durability, visual appeal, and low-cost, vinyl cladding is very popular in and around Sydney.

Made of a mix of PVC and other materials, vinyl cladding typically comes in the form of horizontally-placed panels. These panels can also be fitted with additional layers of insulation, allowing for greater thermal control within the building.

Compared to alternative cladding options, vinyl is considerably more lightweight, allowing panels to be completely flexible when covering a building. They are also available in countless colours, allowing for greater design versatility.

Timber Cladding

Timber is another popular material choice for cladding. It allows for an aesthetically pleasing finish as well as improved thermal insulation. Timber cladding is also eco-friendly and a great way for building owners to reduce their carbon footprint.

Timber cladding can, however, be costly and tricky to maintain. You’ll likely need to re-paint or re-stain your timber cladding every 3-5 years and take extra care to protect it from pests and rotting.

Stone Cladding

Stone cladding is more common for residential buildings rather than commercial buildings. It provides an elegant, luxurious finish for homes and is easy to maintain and highly effective in preventing moisture from getting in.

The main drawback of stone cladding is that it can be extremely expensive. Both material costs and labour/installation costs are very high.

Metal Cladding

Metal cladding, particularly aluminium cladding, is another very popular choice in Sydney. It provides a shiny and contemporary look for both residential and commercial buildings.

Metal cladding is popular because it’s versatile, easy to work with, lightweight, low-maintenance, cost-effective, and energy efficient. It is, however, susceptible to denting and is a poor sound insulator.

Brick Cladding

Brick cladding is another great option for adding a stylish touch to your building’s exterior. It is highly versatile when it comes to design, allowing for colour and textural customisation.

As brick is a very sturdy material, it provides a high level of protection against the elements and is very easy to maintain.

The installation of brick cladding can incur high labour costs, however, so it is one of the more expensive cladding options.

Glass Cladding

Last but not least, we have glass cladding. This type of cladding is most commonly used on commercial buildings to boost aesthetics and provide a modern and unique feel. It is also a great thermal insulator, requires little maintenance, and is capable of withstanding harsh weather conditions.

Glass cladding can, however, be expensive to install and clean, and is unsuitable for earthquake-prone areas.

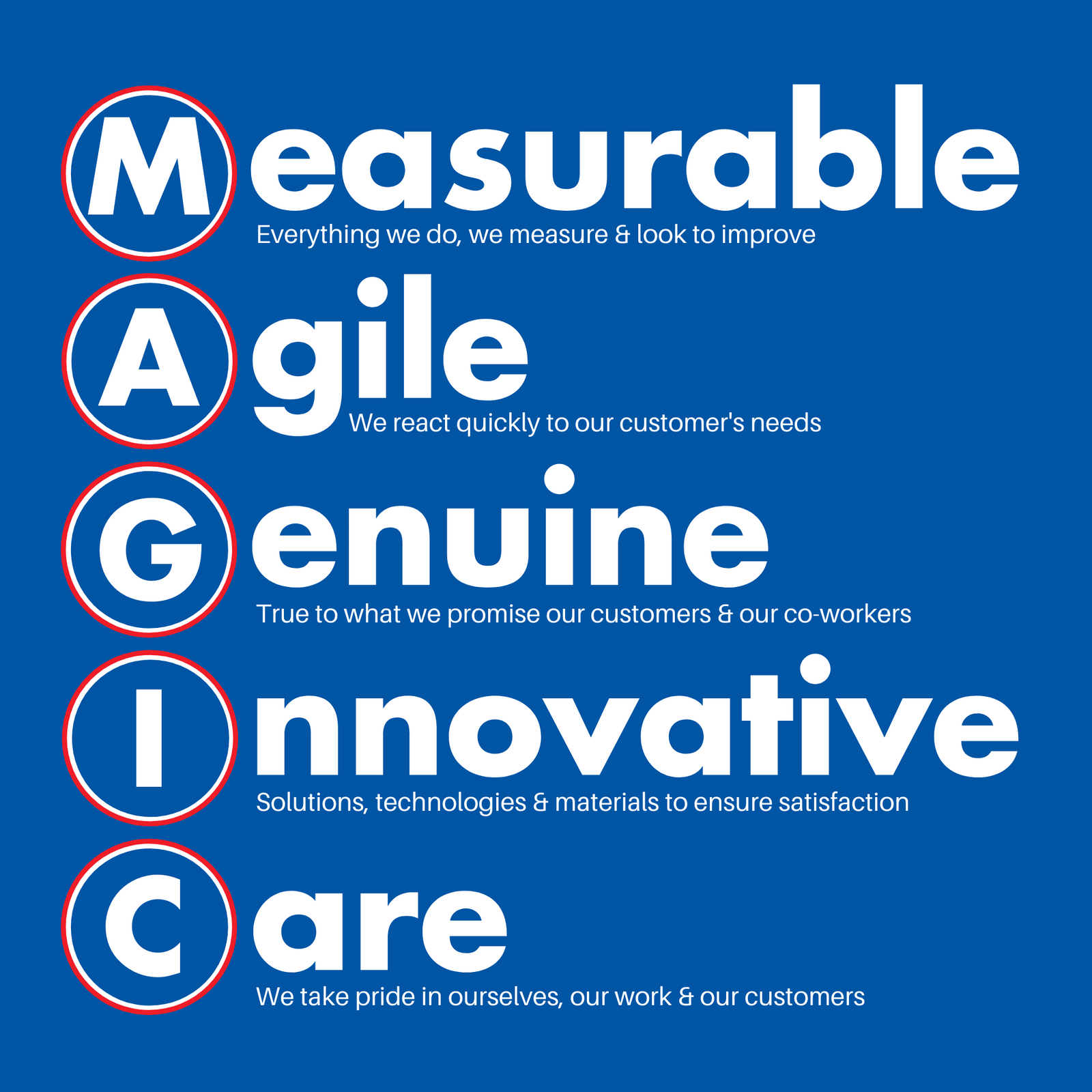

For all your cladding installation, replacement, and maintenance needs, get in touch with Magic Glass. Our dedicated Rope Access Division can offer cost-effective and discrete cladding services for all buildings of all heights.

- Architectural Glass Solutions

- Building Maintenance

- Commercial Glass Installation

- Commercial Glass Replacement

- Commercial Glass Services

- Commercial Glazing

- Custom Glass

- Facade Services

- Glass Installation

- Glass Projects

- Glass Solutions

- Hi-Rise Glass

- High Rise Glass Services

- Rope Access

- Sydney Glass Company

An integrated management system (IMS) is a single system that combines two or more management systems, such as a quality management system (QMS) and an environmental management system (EMS). The goal of an IMS is to integrate the various management systems and processes within an organisation into a single, cohesive system. This can improve efficiency, reduce duplication of effort, and provide a more holistic view of the organisation's operations.

At Magic Glass, our integrated management system has been established in line with the following international standards:

- ISO 9001 Quality Management System

- ISO 14001 Environmental Management System

- ISO 45001 Occupational Health and Safety Management System.

ISO 9001 Quality Management System

ISO 9001 outlines the requirements for a quality management system (QMS). This standard is based on several quality management principles, including a strong customer focus, the motivation and implication of top management, the process approach, and continual improvement.

By implementing a QMS established in line with this standard, Magic Glass has been able to improve our efficiency, reduce costs, and increase customer satisfaction by ensuring our clients get consistent, good-quality glazing and rope access products and services.

ISO 14001 Environmental Management System

ISO 14001 outlines the requirements for an environmental management system (EMS). This standard is used by organisations to help minimise their environmental impacts and ensure compliance with associated regulations.

By implementing an EMS established in line with this standard, Magic Glass has been able to maximise the sustainability of our activities and reduce practices that are potentially harmful to the environment.

ISO 45001 Occupational Health and Safety Management System

ISO 45001 outlines the requirements for an occupational health and safety management system (OHSMS). It helps organisations mitigate the risk of injuries and illness in the workplace.

By implementing an OHSMS based on ISO 45001, Magic Glass has been able to minimise the occurrence of injuries and illnesses in our workplaces, improve our health and safety performance, and ensure compliance with related regulations.

ISO Certification

In order to become certified in the above international standards, Magic Glass has undergone thorough certification processes and regular audits by ISO representatives. This ensures that we are consistently meeting the requirements of each standard, allowing us to offer top quality, safe, and environmentally-friendly products and services for our customers.

The use of Low-E coated glass has been a game changer in boosting the energy efficiency of buildings. With an estimated 70% of energy loss occurring through windows and doors, and 90% of window energy loss occurring through the glass, Low-E coatings have helped drastically in keeping heat in or out of commercial buildings and houses.

What is Low-E Glass?

Low-E (or low-emissivity) glass is designed to minimise the amount of infrared and UV radiation absorbed by glass, without reducing the amount of light entering the building.

The glass has a very thin, transparent coating that reflects heat back inside or outside the building. This helps keep the temperature in your building consistent by reflecting the internal temperature back inside.

Types of Low-E Coatings

There are two different types of Low-E coatings. Which one is best for you is based predominantly on your area’s climate.

Hard-Coat (Passive) Low-E Coatings

Hard-coat Low-E coatings are applied to glass immediately after it is removed from the furnace. The heat causes the coating to fuse onto the glass as it is cooling down. The fusion creates a strong bond (or hard-coat) that is highly durable.

Hard-coat Low-E glass is used predominantly in climates where the temperature can get extremely low. This is because the hard-coat glass allows some of the sun’s short-wave infrared energy to pass through, whilst keeping the long-wave heat energy inside. This keeps buildings nice and warm when it is cold outside.

Soft-Coat (Solar Control) Low-E Coatings

Soft-coat Low-E coatings are applied to pre-cut glass in a vacuum chamber once the glass has cooled. This type of coating must be sealed in an insulated glazing unit (IGU) or laminated glass unit for longevity and optimal performance.

Soft-coat Low-E glass has lower emissivity and higher solar control performance. It has better UV protection and is overall more effective. For this reason, it is ideal for use in cold to hot climates where it can reflect the warm or cool air back into your building, with minimal leakage outside.

Installing Low-E glass into your home or business can significantly improve your building’s energy efficiency, in turn reducing your carbon footprint and saving you money. It can also prevent damage to your furniture and internal decor by blocking out harmful UV rays.

If you’re considering upgrading to Low E glass, contact the Magic Glass team today! We can provide you with a free quote and help advise you on what options are best for your building.

- Commercial Glass Replacement

- Commercial Glass Services

- Custom Glass

- Custom Glass Installation

- Energy Efficient

- Glass Company

- Glass for Home

- Glass Options

- Glass Replacement

- Glass Services

- Glass Solutions

- Glass Window Replacement

- Glazing Services

- Residential and Commercial

- Sydney Glass Company

- Window Replacement Service

- Window Services

When it comes to Rope Access, an acronym that is frequently thrown around is IRATA. If you’ve heard this acronym but are unsure as to what exactly it means, this article is for you.

What is IRATA?

IRATA stands for the Industrial Rope Access Trade Association. This association was established in the United Kingdom in the 1980s as a means for providing a safe working environment in the oil and gas industry.

As these industries began to employ a number of industrial rope access techniques, it was recognised that ensuring these practices were safe was an important factor in maximising workplace health and safety. From this, IRATA developed their own rope access technique that emphasised safety and could be used in a range of repair, maintenance, inspection, and access work.

IRATA is now recognised as the world’s leading authority on industrial rope access. It has over 570 member companies globally and has trained roughly 130,000 Rope Access Technicians from a multitude of different countries.

IRATA directs and regulates the training of all Rope Access Technicians seeking IRATA qualifications and certifications.

What Does IRATA Do?

IRATA’s main activities include:

- Regulating the IRATA system as used by their members.

- Reviewing and updating policies and procedures relating to standards, audit, and assessment.

- Promoting and maintaining a high standard of industrial rope access activities in terms of safety and quality.

- Providing guidance and training of personnel involved in industrial rope access.

- Producing publications and guidance on safety, good working practices, training, and other related topics.

- Preparing submissions and providing opinions and advice to global government departments and organisations surrounding work at-heights, health and safety, and training.

- Ensuring safe rope access training and work procedures are introduced and developed.

- Supporting members with enquiries.

- Organising annual events for the rope access community.

What are the Objectives of IRATA?

The main aims of IRATA are as follows:

- To promote and maintain high standards in safety and work quality of practices in the industrial rope access industry.

- To improve the practices of individuals working in rope access.

- To promote continuous improvement in the education and training aspects of rope access.

- To increase awareness surrounding the advantages of rope access over alternative access methods.

IRATA plays a paramount role in promoting and encouraging safe rope access practices around the world. They offer thorough training and certification programs for Rope Access Technicians to ensure they maintain a high standard of safety and quality when carrying out work at-heights.

At Magic Glass, all our Rope Access Technicians are IRATA trained and certified. This ensures all our practices are of the highest safety standards, and all our work is of the best possible quality.

For any repair, maintenance, and installation requirements at-heights or in hard-to-access areas, get in contact with the Magic Glass Rope Access Division now!

Although rope access may appear scary to many, it is actually the safest option when it comes to height access work.

Compared to alternative methods such as scaffolding and cranes, rope access has very little risk. This is due to several factors outlined below.

1. Full Accreditation Required

In order to become a Rope Access Technician in Australia, you must be fully accredited and IRATA trained.

All Rope Access Technicians at Magic Glass undergo thorough training before they are permitted to work. This enables them to become familiar with all safety procedures and protocols and understand how to tackle all jobs at-height as safely as possible.

2. Less Equipment, Less Risk

Compared to using scaffolding or cranes, rope access requires very little equipment and set-up.

Because of this, there is less space where something could go wrong and less equipment that could fail.

3. Less Time, Less Risk

Rope access is also by far the fastest and most efficient method of height access work.

Because of this, there is less time for complications to arise or for something to go wrong.

4. Safer for Passer-Byers

Rope access is also much safer for passer-byers of the building or construction site.

This is because all tools required for the job at hand are secured to Technicians via ropes and harnesses. In the event that a Technician accidentally drops their tool, it will stay intact to the Technician instead of falling to the ground and potentially harming pedestrians and other workers on the way.

For all your rope access needs, get in contact with the Magic Glass team.

All of our dedicated Rope Access Technicians are highly experienced and IRATA trained.

Concrete cancer is an issue all building managers and owners should be familiar with. It can occur in any building and, if left untreated, can vastly affect its structural integrity.

What is Concrete Cancer?

Concrete cancer occurs when the steel reinforcements in a concrete slab begin to corrode. This causes the surrounding concrete to become brittle and crack, which can have drastic effects on both the functionality and visual appeal of the building.

Concrete cancer occurs most commonly when the steel reinforcements are exposed to air and water.

What are the Signs of Concrete Cancer?

Common signs of concrete cancer include:

- Cracking or crumbling concrete

- Rust stains emerging from the concrete

- Bubbling of the concrete render

- Leaks in internal walls.

What are the Causes of Concrete Cancer?

Concrete cancer can occur for a number of reasons. The mains ones being:

- Poor waterproofing

- Saltwater chlorides forming in buildings near the sea

- Harsh/wet weather conditions

- Concrete carbonation

- Poor quality concrete

- Insufficient concrete cover

- Ground movement under the building.

How do you Treat Concrete Cancer?

Concrete cancer treatment is predominantly dependent upon the cause of the problem. In the event of concrete carbonation or insufficient concrete cover, most technicians will opt for the application of a polymer modified repair system to the steel reinforcements of the concrete slabs.

In the event of weather damage or the formation of saltwater chlorides, it is common to treat concrete cancer with electrochemical treatment options, such as cathodic protection.

The worse the concrete cancer is, the harder it will be to treat. Early diagnosis is therefore key in preventing further structural damage and saving you money .

If you spot any signs of concrete cancer in your structure, you should contact Magic Glass as soon as possible.

Our qualified technicians will be able to identify the causes of your concrete cancer and inform you on your options for remediation. We also have a specialised Rope Access Division, so we can access all areas of your building, no matter its size.

Call us today for a free quote.

- 24 Hour Emergency Glass Replacement

- 24 Hour Emergency Glass Services

- Broken Window

- Commercial Glass Replacement

- Damaged Window

- Emergency Window Replacement

- Emergency Window Services

- Glass Company

- Glass Replacement

- Glass Services

- Glass Window Services

- Glazing Glass Services

- High Rise Glass Services

- Magic Glass

- Shattered Window

- Sydney Glass Company

- Window Breakage

- 24 Hour Glazing Service

- Custom Cut Glass

- Custom Glass

- Custom Glass Installation

- Emergency Glass Services

- Emergency Glazier Service

- Glass Company

- Glass Services

- Glazier

- Glazing Glass Services

- Glazing Services

- Laminated Glass

- Magic Glass

- Safety Glass

- Shop Window

- Shopfront

- Skylights

- Sydney Glass Company

- Tempered Glass

- Toughened Glass

- Window Glazing