Glass Blog

Concrete cancer is an issue all building managers and owners should be familiar with. It can occur in any building and, if left untreated, can vastly affect its structural integrity.

What is Concrete Cancer?

Concrete cancer occurs when the steel reinforcements in a concrete slab begin to corrode. This causes the surrounding concrete to become brittle and crack, which can have drastic effects on both the functionality and visual appeal of the building.

Concrete cancer occurs most commonly when the steel reinforcements are exposed to air and water.

What are the Signs of Concrete Cancer?

Common signs of concrete cancer include:

- Cracking or crumbling concrete

- Rust stains emerging from the concrete

- Bubbling of the concrete render

- Leaks in internal walls.

What are the Causes of Concrete Cancer?

Concrete cancer can occur for a number of reasons. The mains ones being:

- Poor waterproofing

- Saltwater chlorides forming in buildings near the sea

- Harsh/wet weather conditions

- Concrete carbonation

- Poor quality concrete

- Insufficient concrete cover

- Ground movement under the building.

How do you Treat Concrete Cancer?

Concrete cancer treatment is predominantly dependent upon the cause of the problem. In the event of concrete carbonation or insufficient concrete cover, most technicians will opt for the application of a polymer modified repair system to the steel reinforcements of the concrete slabs.

In the event of weather damage or the formation of saltwater chlorides, it is common to treat concrete cancer with electrochemical treatment options, such as cathodic protection.

The worse the concrete cancer is, the harder it will be to treat. Early diagnosis is therefore key in preventing further structural damage and saving you money .

If you spot any signs of concrete cancer in your structure, you should contact Magic Glass as soon as possible.

Our qualified technicians will be able to identify the causes of your concrete cancer and inform you on your options for remediation. We also have a specialised Rope Access Division, so we can access all areas of your building, no matter its size.

Call us today for a free quote.

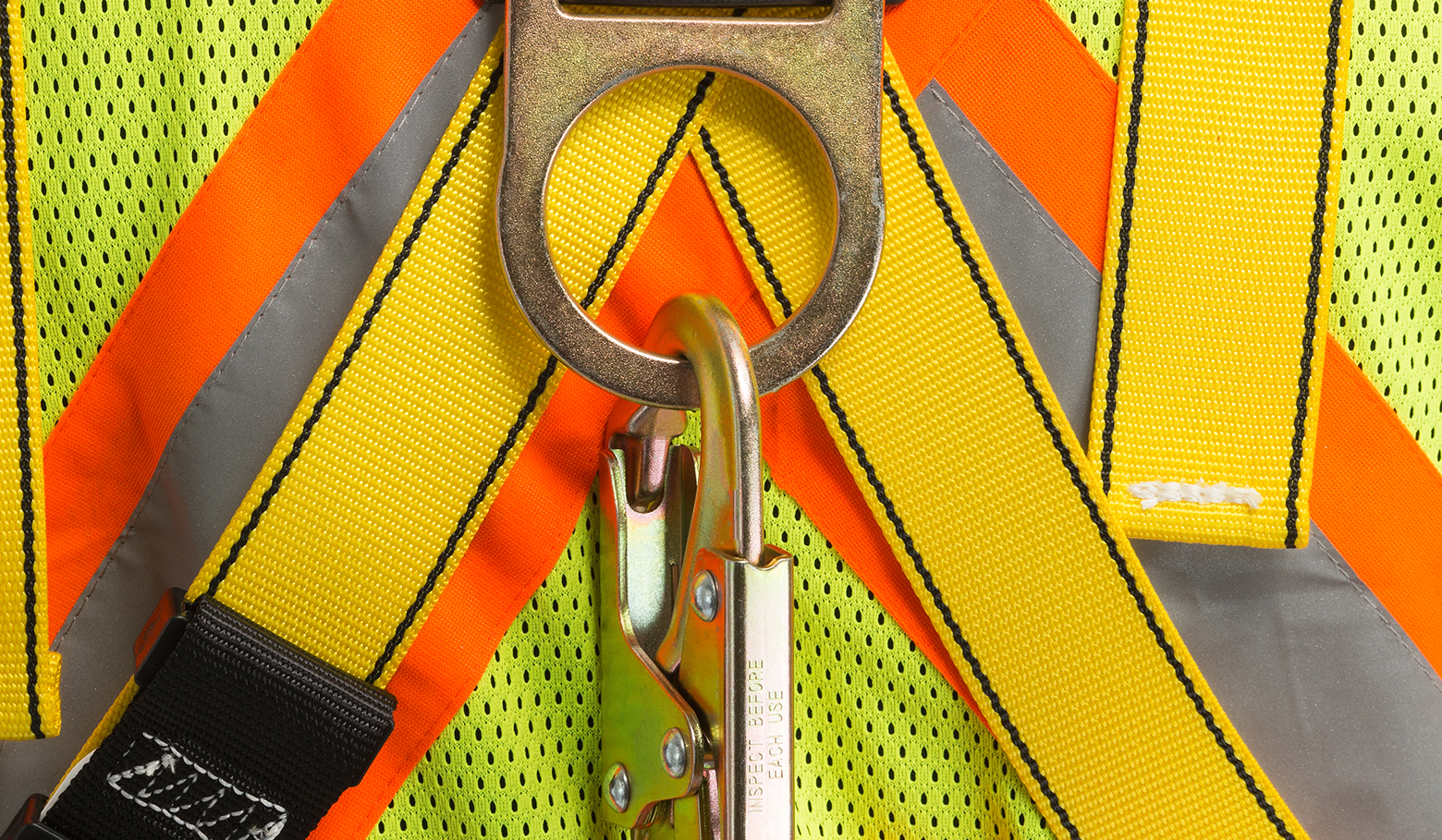

Fall arrest systems are an important part of all at-height construction and work sites. They play a critical role in reducing workplace injuries and fatalities caused by falls. To learn more about fall arrest systems and the different types, read on.

What are Fall Arrest Systems?

A fall arrest system protects workers in the event of a fall. If a person working near an unprotected edge should take a fall, the fall arrest system combined with a fall arrest harness will catch the person and prevent them from hitting the ground or area below.

It’s important to note that fall arrest systems are different to fall prevention systems. Fall arrest systems protect workers after they’ve fallen, whilst fall prevention systems prevent the occurrence of falls (such as edge protection and roof guardrails).

What are the Different Types of Fall Arrest Systems?

Fall arrest systems can be categorised as either general or personal. General fall arrest systems include nets and catch platforms, whilst personal arrest systems include lanyards and harnesses.

Some of the most common types of fall arrest systems include:

- Static Lines

- Anchor points

- Rope grabs

- Safety nets (ideal for worksites where there are no scaffolds, and the fall hazard is less than 25 metres)

- Rails

Many of these fall arrest systems involve anchor points. These are points where workers can attach their lanyards to anchor themselves to the building and catch them in the event of a fall.

Like all fall arrest equipment, it is important to get anchor points inspected regularly and ensure they are certified for use. All height Safety systems must be inspected and certified every 12 months by a certified professional.

When Should Fall Arrest Systems be Used?

Fall arrest systems should always be used when working at a height that could potentially cause injury in the event of a fall. This may include when carrying out electrical, glazing, cleaning, and roofing work.

Even if the risk of injury is minimal, at least one form of fall protection should always be used.

If you require height safety installation, get in contact with the Magic Glass team. We are highly experienced in installing, inspecting, and certifying a range of different height safety hardware including fall arrest systems, anchor points, safety ladders, ladder points, and temporary and permanent edge protection.

- 24 Hour Emergency Glass Repairs

- 24 Hour Emergency Glass Replacement

- 24 Hour Emergency Glass Services

- 24 Hour Glazing Service

- After Hour Glass Replacement

- Emergency Board Up Service

- Emergency Door Replacement

- Emergency Glazier Service

- Emergency Window Replacement

- Emergency Window Services

- Magic Glass

- Open 24 Hours

- Same Day/Next Day Service